State of the art class 10,000 cleanroom

- Cleanroom Assembly

- Cleanroom Packaging

- Laser Welding

- Laser Marking

Automated 4 stage immersion Ultrasonic Washline

- Citric Passivation

- Ultrasonic Washing

- Particulate Testing

- Non-Volatile Residue Testing

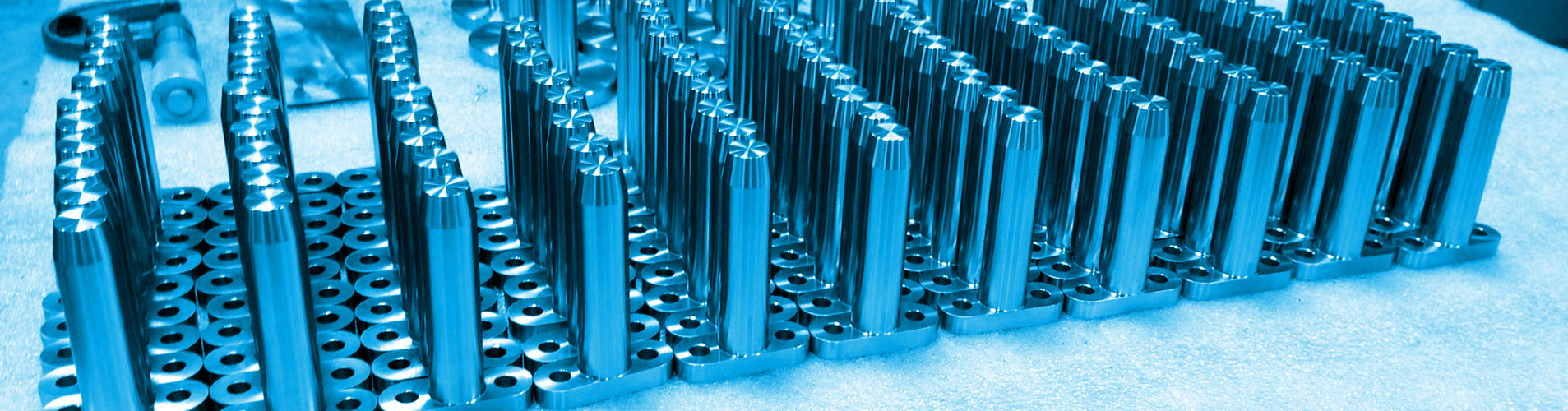

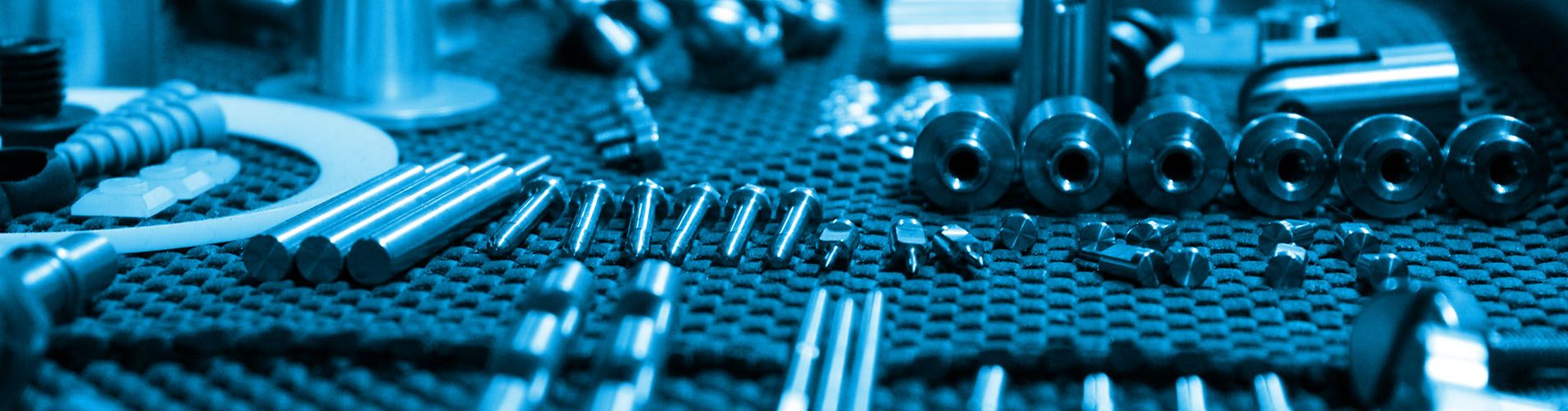

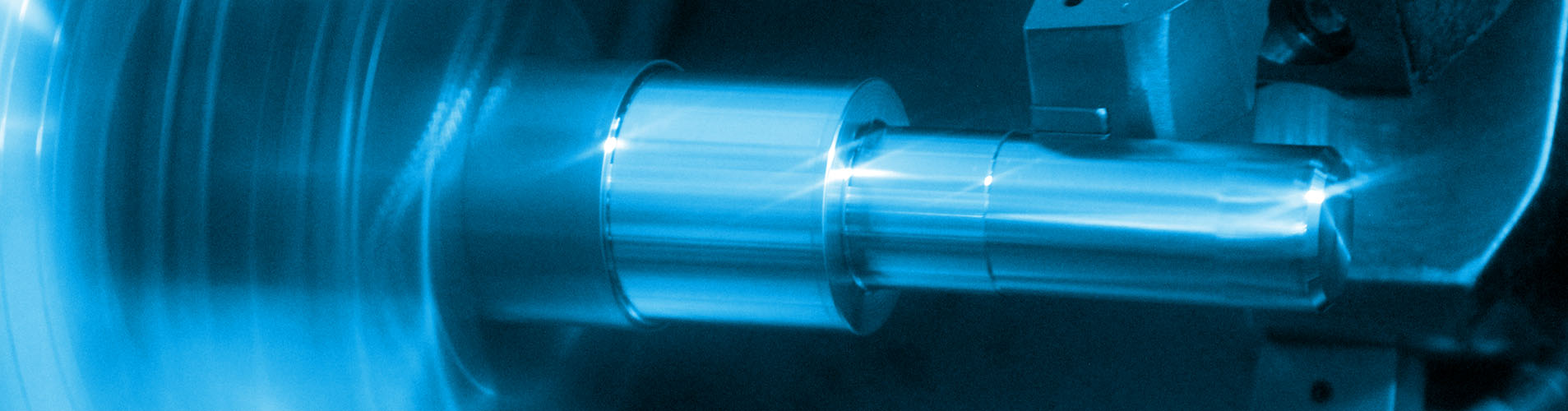

World Class manufacturer of custom machined components

- 3, 4, & 5 Axis Machining

- Turning (Live Tooling)

- Swiss Turning

- Wire EDM

- Waterjet Cutting

- Additive Manufacturing (3D Printing)

Trinity Precision Solutions services a variety of industries by specializing in:

- Cleanroom device assembly

- Advanced CNC machining

- Ultrasonic washing and passivation

- Speedy prototype builds

Precision Manufacturing for Medical & Critical Industries

Trinity Precision Solutions (TPS) is a contract manufacturer delivering high-precision components and assemblies to the Medical Device, Aerospace, Automotive, Electronics, and Defense markets. Since 2008, we’ve supported OEMs and product development teams with turnkey manufacturing, from rapid prototypes to full-scale production.

We perform cleanliness testing inside the cleanroom to validate bioburden and particulate control before packaging, ensuring components meet strict medical manufacturing requirements. Laser marking on flat and cylindrical components supports full lot traceability throughout the supply chain.

ISO-Certified. Cleanroom Ready. Medical Focused.

TPS maintains ISO 9001:2015 and ISO 13485:2016 certifications, ensuring full compliance with medical device quality and traceability requirements. Our facility features a Class 10,000 (ISO 7) medical cleanroom engineered for contamination control during:

- Critical component cleaning

- Ultrasonic wash processing

- Inline citric passivation

- Medical packaging and final assembly

Our Sister Company

Advanced Manufacturing Capabilities

Our in-house equipment allows us to manage complex geometries, tight tolerances, and aggressive timelines:

- 3-axis & 5-axis CNC machining

- CNC Swiss turning & live-tooling turning centers

- Wire EDM

- Waterjet cutting

Whether you need a single prototype or thousands of units in production, TPS delivers consistency and repeatability across every manufacturing stage.

Why Med-Device Companies Choose TPS

- Contamination-controlled cleanroom environment (ISO 7)

- Full lot traceability and documentation

- Fast response times and flexible production scheduling

- Seamless prototype-to-production transition

- Dedicated customer support and project management

Let’s Build Your Next Breakthrough!

Whether you’re developing a new sterile instrument, implant component, or a precision mechanical assembly, TPS is ready to support your success.