Trinity Precision Solutions, Inc. specializes in cleaning and passivating parts and components for almost every industry or application that requires critical cleaning on metal surfaces. Our extensive experience of specifications and procedures enables us to meet any customer or end-user requirements.

We are well suited for processing hardware and components related to the following industries, as well as other markets requiring these precision services:

- Medical Devices

- Aerospace

- Automotive

- Electronics

Our complete cleaning process removes contaminants that affect the passive layer. For Stainless Steel surfaces, an optimal passive layer provides corrosion resistance. A passive layer surface will inhibit oxidation, thus minimizing contamination.

Our flexible approach means we recommend just the right cleaning method for the materials and devices being assembled based on current industry standards and your requirements.

TPS only uses approved chemistry and cleaning processes to provide certification to meet customer specifications.

We offer a vast range of passivation and cleaning services to ensure that your components meet the highest industry standards for cleanliness before assembly and packaging.

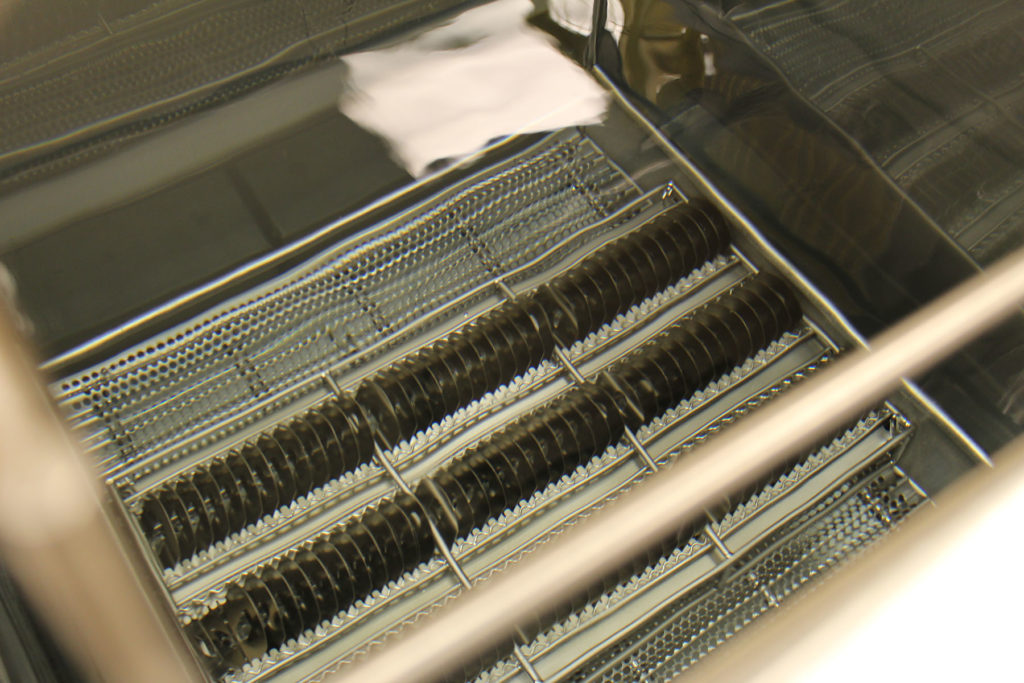

Our capabilities include:

- Pharmaceutical water system

- Solvent and detergent cleaning

- Ultrasonic cleaning

- IPA wipe or dip

- Citric acid passivation (Environmentally friendly)

- Cleaning process validation studies

- Particulate testing

Industries Served

- Medical

- Aerospace

- Automotive

- Electronics

- Defense