Trinity Precision Solutions (TPS) offers advanced CNC turning and Swiss-type machining services designed to meet the evolving needs of industries requiring tight-tolerance, small diameter, and geometrically complex parts. Our cutting-edge equipment and expertise allow us to deliver unparalleled precision, efficiency, and surface finishes for medical devices, aerospace, automotive, electronics, and defense applications.

Swiss CNC Turning Capabilities

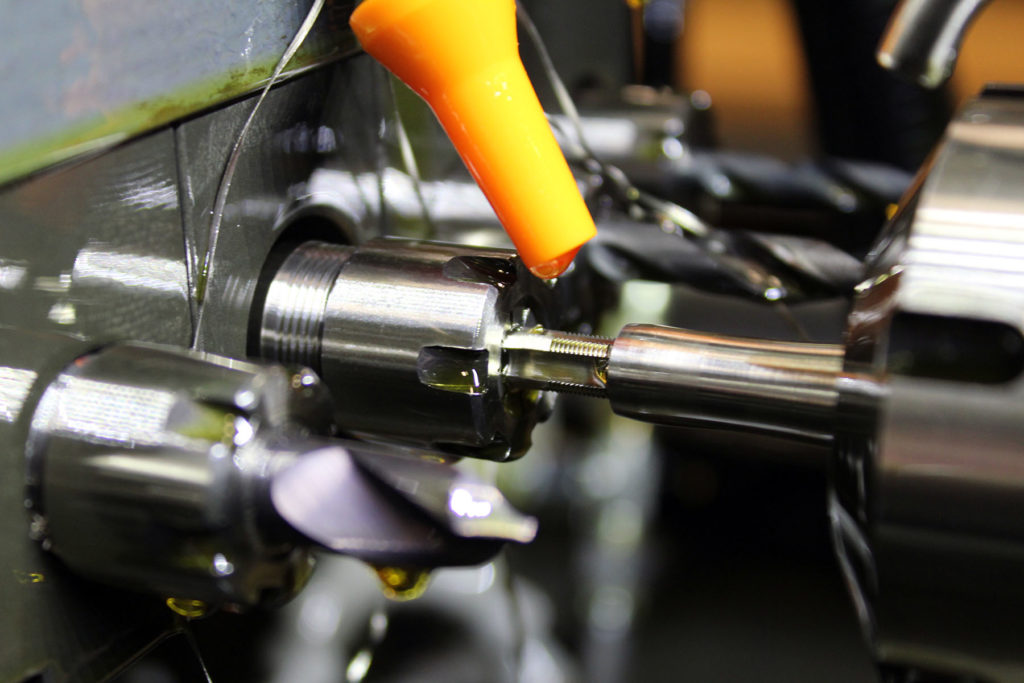

Our Tornos Swiss-type turning center with live tooling provides seven linear axes, two “C” axes, and a modular tooling setup, enabling multiple operations to be performed simultaneously. With an automated bar feeder up to 1” diameter, this machine delivers high throughput and maximum productivity for small, complex components.

Swiss Turning Specifications:

- Bar capacity: 1” diameter

- Maximum part length: 6”

- Minimum diameter: 0.060”

- 7 linear axes + 2 “C” axes

- Live tooling for milling, drilling, reaming, and deep boring

Our CNC turning centers accommodate larger parts with diameters ranging from ¼” up to 14” and lengths up to 22”, providing flexibility for a wide range of component sizes and geometries. Secondary operations are often eliminated, as internal and external milling, drilling, threading, and other integral operations can be completed in a single setup.

CNC Turning Specifications:

- Minimum diameter: ¼”

- Maximum diameter: 14”

- Maximum length: 22”

Why Choose TPS for CNC Turning & Swiss Turning

- Produce close-tolerance parts with superb surface finishes

- Swiss turning for small-diameter, high-precision components

- Integrated secondary operations reduce lead times and improve efficiency

- Flexible production for prototypes to high-volume runs

- ISO-certified quality systems for traceability and compliance

Industries Served

- Medical

- Aerospace

- Automotive

- Electronics

- Defense