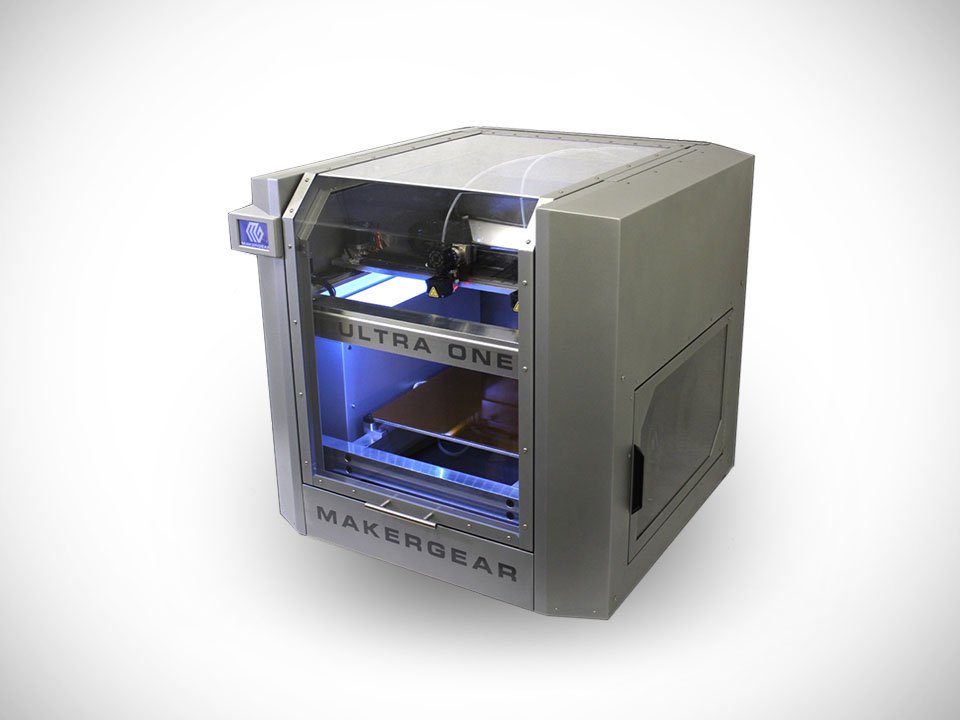

To save you time and money we have invested in a Makergear Ultra One 3D printer. It is capable of printing 16“wide x 14” deep x 13” high utilizing independent dual extruders. A high temperature capability enables TPS to print a wide variety of materials such as nylon, polycarbonate, polypropylene, metal composites and more.

- Nylon

- Polycarbonate

- Polypropylene

- Carbon fiber composites

- Metals

With the ability to produce different parts of various shapes without using expensive tooling, 3D printing offers flexibility for production. Manufacturing requires a number of different steps to produce a part and not one step can be missed. With 3D printing however, designing of the part and uploading it to the printer are all that’s required.

Another clear advantage of 3D printing is that it only uses the required material to create a part which means minimal waste and very little labor.

Industries Served

- Medical

- Aerospace

- Automotive

- Electronics

- Defense