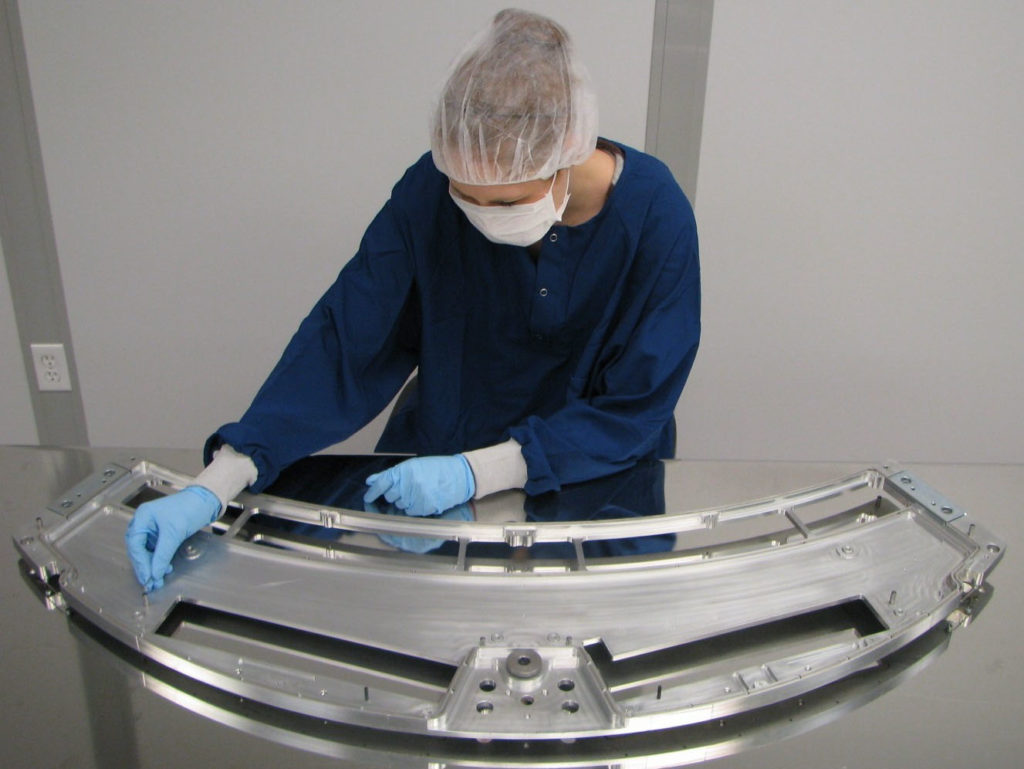

As a fully equipped solutions provider, Trinity Precision Solutions (TPS) provides a vast range of cleanroom assembly services inside our state-of-the-art Class 10,000 Cleanroom. Being both ISO 9001:2015 certified by NQA and ISO 13485:2016 certified by NQA, we build custom assemblies, displaying a high level of quality that complies with all relevant regulatory requirements.

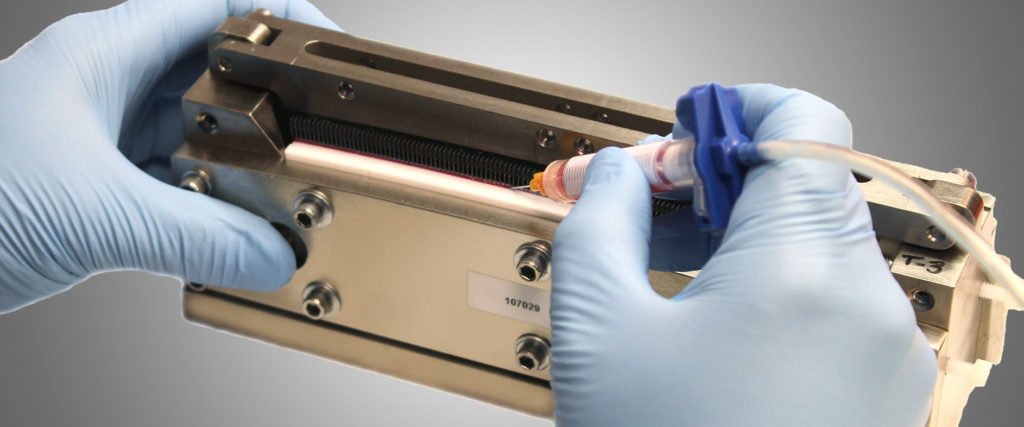

TPS offers micro-welding and a wide spectrum of mechanical assembly capabilities including Adhesive Assembly and Snag Fit Assembly. We have the proficiency and expertise across an infinite range of sensitive products, covering a multitude of sizes and complexities.

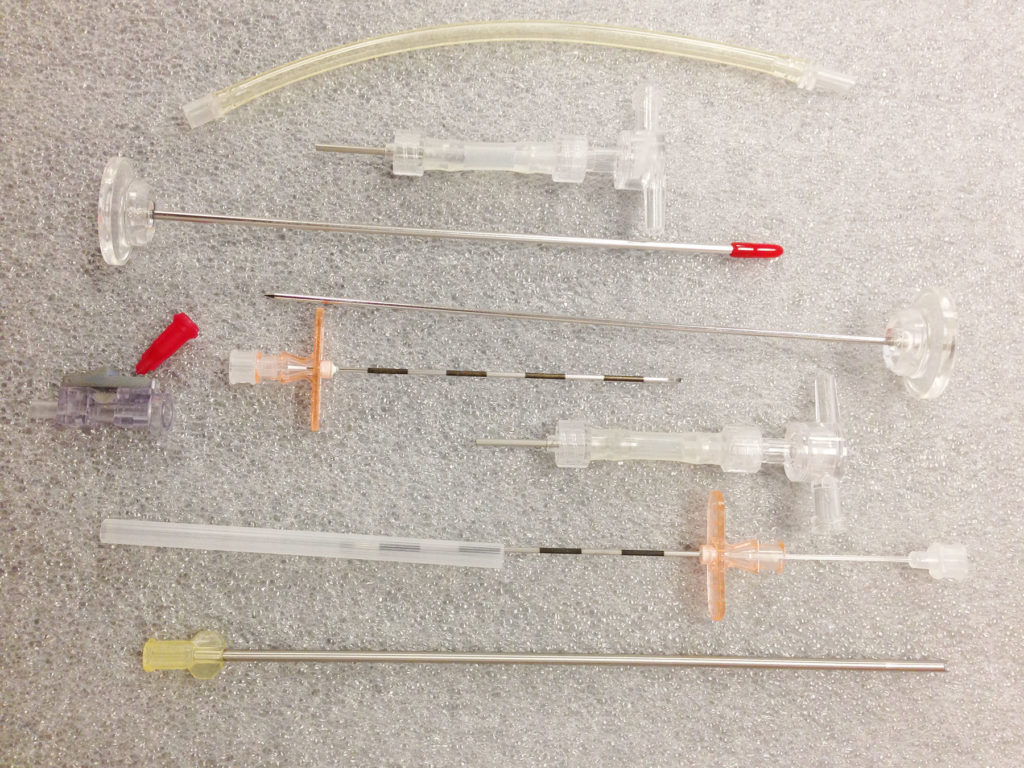

- Respiration

- Ventilation

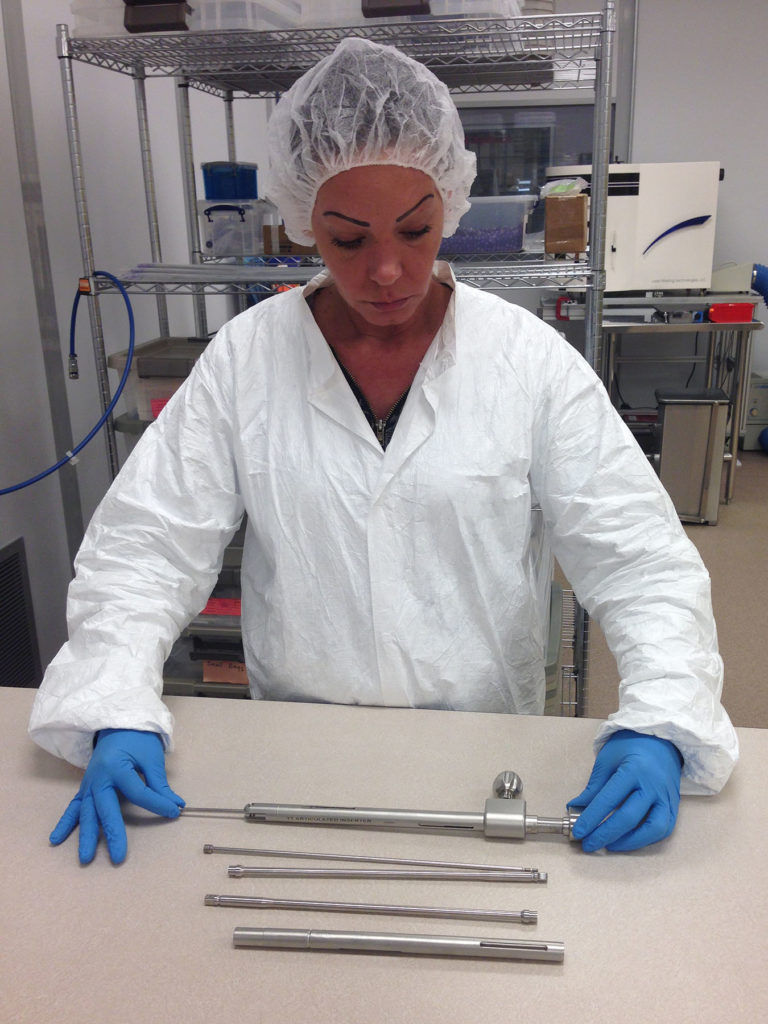

- Orthopedic instrumentation

Trinity Precision Solutions also offers Ultrasonic Welding among our vast range of capabilities. Powered by high frequency electrical energy, ultrasonic welding fuses plastic/plastic and plastic/metal components together through frictional heat.

As a benefit to our cleanroom, we utilize a variety of mechanized test equipment to verify the quality of your assembled products. We inspect using our CMM’s, to take precise 3-D measurements. Our high-end Faro laser arm scanner & automated vision system are used for inspection and CAD comparison.

- Medical

- Aerospace

- Automotive

- Electronics

- Defense

Different Types of Assemblies

Industries Served

- Medical

- Aerospace

- Automotive

- Electronics

- Defense