At Trinity Precision Solutions (TPS), we provide end-to-end cleanroom packaging services engineered for medical devices, combination products, and other contamination-sensitive components. Our Class 10,000 (ISO 7) cleanroom, certified to ISO 13485:2016 by NQA, ensures every product is packaged in a controlled environment to maintain sterility, traceability, and regulatory compliance.

Cleanroom Packaging Capabilities:

• Pouch and bag sealing

• Vacuum sealing

• Shrink wrapping

• Custom sterile packaging and kitting

• Instrument assembly and packaging

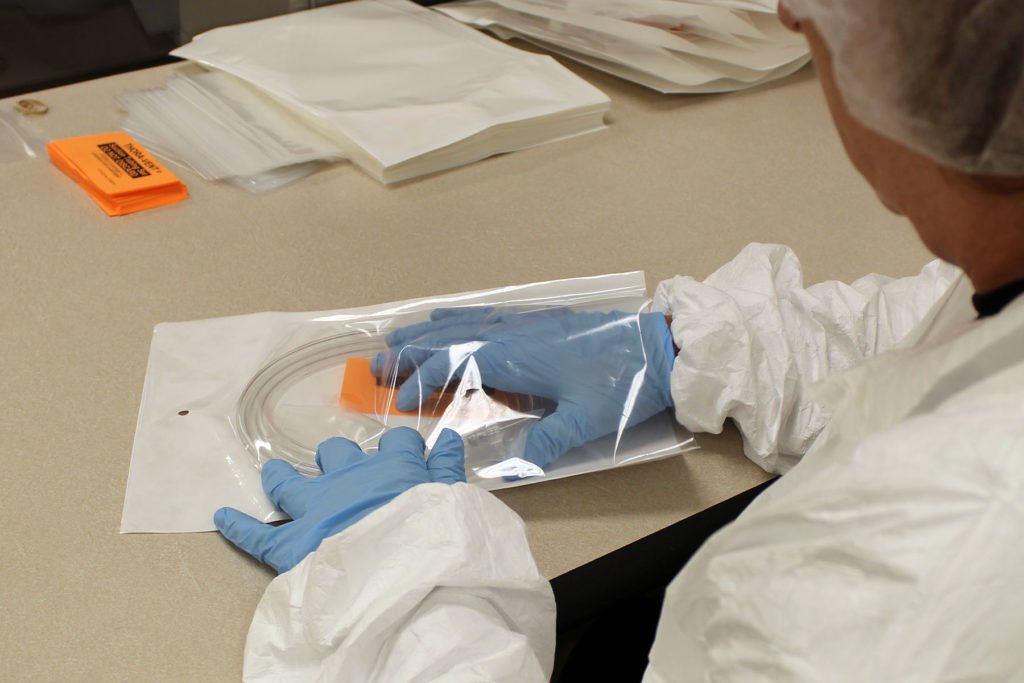

• Tubing sets (cutting, fitting, and assembly)

• Packaging for combination devices

We support a wide range of sterile barrier packaging formats, including:

- Tyvek® breather bags

- Chevron peel pouches

- PVC trays and custom inserts

Every packaging process follows documented procedures to ensure product integrity, contamination control, and consistent results. Assemblies and packaging steps are verified by our Quality Department for full traceability throughout the cleanroom workflow.

TPS utilizes the latest cleanroom packaging technologies to meet industry-specific requirements across medical, aerospace, and other regulated markets, providing efficiency, reliability, and validated packaging solutions from prototype to production.

Request a Cleanroom Packaging Quote

Industries Served

- Medical

- Aerospace

- Automotive

- Electronics

- Defense