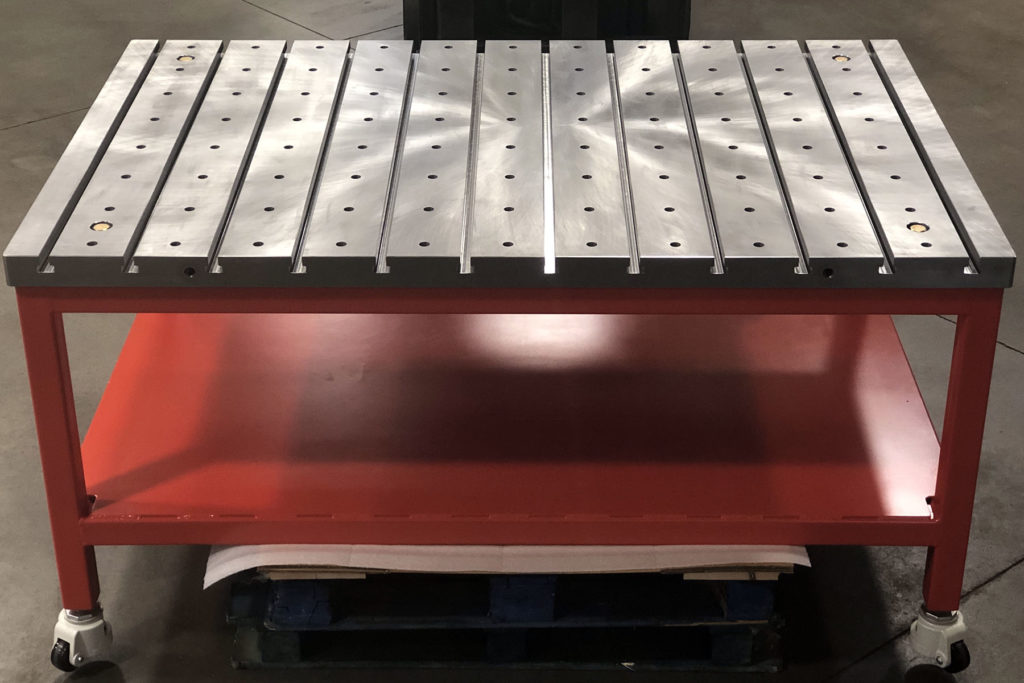

Trinity Precision Solutions (TPS) expands its manufacturing capabilities with expert custom fabrication and specialty fixture production. We create one-of-a-kind assemblies and fixtures in steel, stainless steel, aluminum, and tool steel, supporting industries such as automation, robotics, aerospace, and many more. Many of our fabricated assemblies are designed for precision workholding and efficient material handling in complex equipment.

Fabrication Capabilities

- Custom metal fabrication from prototype to production

- Heat-free precision waterjet cutting for weld-ready parts

- MIG, TIG, and laser welding services

- Plate, tubular, and structural fabrication

Our fabrication process ensures tight tolerances, high-quality finishes, and structural integrity for every part. By combining advanced cutting, welding, and assembly techniques, TPS delivers fixtures and fabricated assemblies that meet the most demanding industry specifications.

Materials Fabricated

- Stainless steel

- Carbon steel

- Aluminum and aluminum alloys

- Tool steel

When your next project requires high-precision custom fabricated fixtures or assemblies, TPS delivers quality, accuracy, and reliability from concept to completion.

Industries Served

- Medical

- Aerospace

- Automotive

- Electronics

- Defense